Aluminum Foundry review prepared in a organized style

Wiki Article

Discover the Duty of Metal Shops in Modern Production Processes

Metal shops are indispensable to the manufacturing landscape, converting raw products right into necessary parts for various industries. Their advanced methods, consisting of 3D printing and CAD, allow the creation of complex get rid of minimal waste. In addition, shops are increasingly adopting lasting techniques to enhance their environmental footprint. Recognizing the complete scope of these operations exposes their significant influence on markets such as vehicle and aerospace, prompting a closer evaluation of their developing function in contemporary manufacturing.The Essential Features of Steel Shops

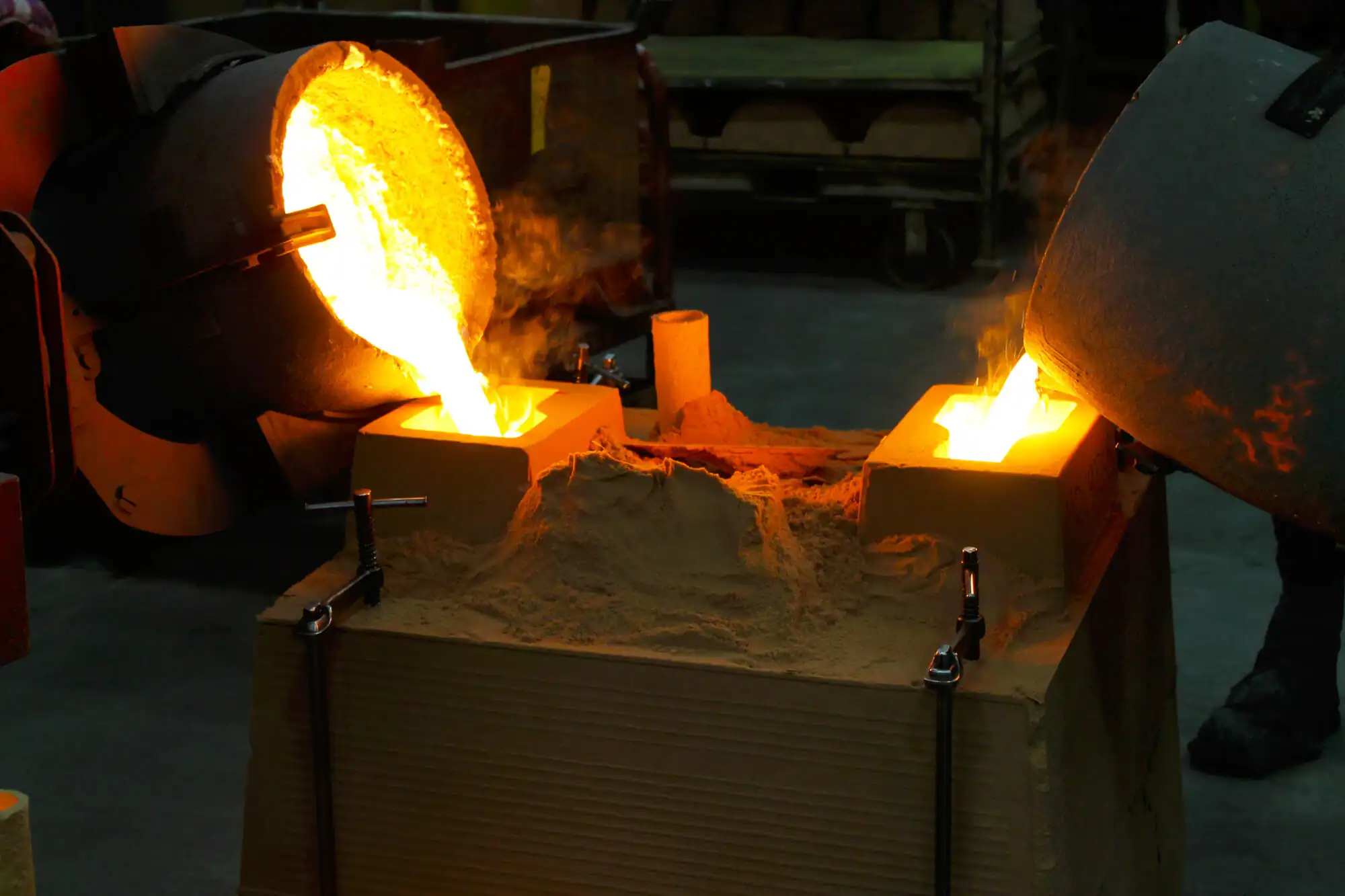

Metal shops play an important duty in the production sector by changing basic materials into functional metal products via different procedures (Aluminum Foundry). These facilities are very important for creating elements used in many markets, including auto, aerospace, and building and construction. Shops mostly focus on melting metal alloys and putting them into molds to develop details forms, a procedure known as spreading

Furthermore, shops supply customized solutions, such as warm treatment, which improves the mechanical residential properties of metal products. By assisting in these important features, metal foundries add considerably to the total efficiency and advancement within the manufacturing landscape, allowing the manufacturing of a wide variety of metal items.

Advanced Technologies in Steel Casting

As the production industry progresses, progressed modern technologies in steel casting are reshaping the landscape of manufacturing. Technologies such as 3D printing and computer-aided design (CAD) have considerably improved the effectiveness and precision of casting procedures. These technologies allow factories to generate intricate geometries that were difficult or previously challenging to attain, therefore reducing material waste and enhancing general high quality.In addition, automation and robotics have structured procedures, minimizing manual labor while increasing manufacturing speed. Integrating advanced simulation software application enables factories to enhance casting styles and predict potential defects prior to manufacturing, additionally boosting integrity.

In addition, the advent of smart manufacturing systems, including the Web of Things (IoT), facilitates real-time surveillance of processes, making sure better control over production parameters. These technical developments not just drive cost-effectiveness however additionally setting metal foundries at the center of modern manufacturing, allowing them to meet the progressing demands of numerous industries.

Sustainability Practices in Foundries

While the production market encounters boosting pressure to take on environmentally liable methods, foundries are proactively carrying out sustainability actions to lower their environmental impact. Numerous shops have actually accepted reusing efforts, making use of scrap metal and various other materials to lessen waste and preserve resources. Advanced modern technologies, such as energy-efficient furnaces and automated procedures, further improve their dedication to sustainability.Shops are also concentrating on improving and decreasing exhausts air high quality by taking on cleaner production techniques. Making use of ecologically pleasant binders and finishes has obtained grip, decreasing dangerous by-products in the casting procedure. Furthermore, water conservation measures are being implemented, with closed-loop systems reducing freshwater intake and wastewater discharge.

The Impact of Foundries on Various Industries

Although usually forgotten, foundries play a necessary function in supplying vital components across a varied series of markets. These centers are important in producing metal castings used in automobile, construction, equipment, and aerospace fields. In the auto sector, factories supply engine blocks, transmission situations, and other crucial elements, making sure vehicles operate effectively. Aerospace counts greatly on precision-cast components that fulfill stringent security criteria, while building companies rely on solid and durable metal products for framework projects.

Moreover, foundries add to the energy field by making parts for power generation tools, consisting of wind turbines and generators. Their adaptability includes consumer goods, where cast steel parts enhance item functionality and resilience. By supporting various industries, foundries not just boost producing abilities yet likewise drive innovation and technological advancements, emphasizing their considerable effect on the global economic climate.

Future Fads in Metal Factory Workflow

Arising technologies and progressing market needs are forming the future landscape of metal foundry operations. Automation and robotics are significantly being integrated to boost performance and decrease labor expenses. Smart factories are leveraging information analytics and the Net of Things (IoT) to check production processes in real-time, assisting in anticipating maintenance and minimizing downtime.Sustainability is also becoming a focal point, with factories embracing greener methods by recycling materials and lowering energy consumption. Advanced products, such as light-weight alloys and compounds, are gaining grip, driven by sectors like aerospace and automotive looking for improved efficiency.

Additive production is arising as a corresponding innovation, enabling the manufacturing of complex geometries that typical approaches can not achieve. As digitalization proceeds, metal factories are anticipated to adopt more adaptable production systems, permitting customized, on-demand production solutions. These trends show a transformative shift, placing metal shops for a dynamic future in production.

Regularly Asked Inquiries

What Materials Are Commonly Made Use Of in Metal Shops?

Metal shops generally utilize materials such as iron, aluminum, bronze, brass, and various alloys. his comment is here These materials are chosen for their special residential or commercial properties, making it possible for the production of varied components customized for details applications in various sectors.How Do Foundries Make Sure Quality Assurance in Manufacturing?

Foundries carry out rigorous quality control steps, consisting of material examinations, process monitoring, and screening of ended up items. They utilize sophisticated technologies and standards to ensure adherence, uniformity, and integrity to specifications throughout the production process.What Precaution Are Carried Out in Metal Factories?

Steel foundries execute security actions such as individual safety tools, air flow systems, routine safety training, and emergency procedures. These techniques intend to minimize risks related to high temperature levels, poisonous fumes, and hefty machinery procedures.How Long Does the Steel Casting Process Typically Take?

The steel casting procedure usually takes several hours to days, depending upon elements such as the complexity of the design, sort of metal used, and cooling down times needed for the certain casting method utilized.What Are the Profession Opportunities in Steel Foundries?

Job possibilities in steel shops include duties such as shop more information service technicians, metallurgists, high quality control assessors, machine operators, and manufacturing supervisors - Aluminum Casting. These placements provide diverse courses in manufacturing, design, and experienced trades within the industrySteel foundries are essential to the production landscape, converting raw products into essential parts for numerous fields. Metal shops play a crucial duty in the manufacturing sector by changing raw products right into useful steel items through different processes. In addition to casting, steel factories also engage in processes such as machining, where excess product is eliminated to accomplish exact specifications. As digitalization proceeds, steel factories are expected to take on more adaptable production systems, permitting for customized, on-demand production options. Job possibilities in metal factories consist of roles such as site web factory technicians, metallurgists, high quality control assessors, machine drivers, and production managers.

Report this wiki page